Default specifications in international standards

Many international standards use the terme default with a precise meaning. This page explores what defaults imply and how to interprete them, not exactly what it may seem to be...

1. What is a default?

In international standards, the term "default" figures significantly (default filter, default cut-off etc.) Many standards define default values or default rules. ISO 4287 defines the default relationship between λc and λs cut-offs. It also mentions the default height and spacing discriminations to be used for Rc and RSm parameters; ISO 4288 describes a default rule for selection of cut-off wavelength.

However, it seems that users often misinterpret default as meaning recommended.

2. Drawing specifications

In ISO vocabulary, the term “default” actually means "if not otherwise stated on the drawing".

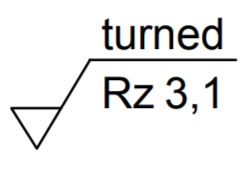

When a roughness specification is given on a technical drawing (see figure), many default specifications are implied and do not actually appear. The value of the parameter given in this specification represents an upper limit because it is the default limit and therefore the symbol U (for upper) is omitted. If a lower value is to be given, then the symbol L (for lower) should be explicitly written in the specification.

The value must be interpreted in micrometers as they are the default unit for parameter specifications. The filter and cut-off are also implicit as the default filter is the Gaussian filter and the default cut-off is 0.8 mm.

All these default values are given in ISO 1302 that describes how to indicate surface texture specifications on technical drawings.

3. Applications in industry

Most ISO Geometrical Product Specifications (GPS) have been published over the last thirty years by and for mechanical engineers with the aim of clearly specifying tolerances on drawings and validating them by measuring the manufactured parts.

Surface texture of mechanical parts depends on the type of machining involved. Several decades of experience in industry have allowed mechanical engineers to correlate parameter values and filtering conditions with mechanical functions, such as sealing, sliding, resistance to wear, lubrication etc. Part of this knowledge is reflected in the default choices used in standards.

4. Non-defaults values

However, users and designers are free to use other values for filters, cut-offs, parameters etc. as long as a functional correlation proving the link between the specification and the expected function has been carried out. In all such cases, they should explicitly specify all context parameters.

For example, small metal parts used in mechanical watches may be specified with shorter evaluation lengths, while larger cut-off values may be specified for diesel engines used in cargo ships. Similarly, users working in different fields that are not covered by these ISO standards (such as the paper industry, the food industry, archaeology etc.) may establish their own specifications.

Key points

Specifications on technical drawings contain implied default conditions

Non-default values must be written explicitly in specifications

Fields of application that are not subject to specifications or are outside the scope of standards may use any other conditions that have been proven useful to control their functions or phenomena

In the context of standards, default does not mean recommended or mandatory