About Surface Function

Depending on the functional role of an engineered surface, all or part of the surface may be taken into consideration when calculating parameters. This page sheds light on this issue and details methods for dealing with it.

Many functions of engineered surfaces involve only part of the surface but not all of it.

For example, when two surfaces are in contact - as in the case of mechanical seals - only portions of these surfaces (the highest peaks and hills) interact with each other. Deep valleys or dales do not have any influence in this case.

Conversely, the ability to retain lubricant in the internal surface of a cylinder bore (to ensure correct sliding of the piston) only depends on grooves and pits.

Despite this, most of specifications on drawings indicate field parameters such as Ra or Wa. Field parameters are calculated using all points of a profile or a surface. Traditional surface texture parameters are usually based on sums of heights.

But did you know that another family of parameters, known as feature parameters, focuses only on particular points or portions of the surface?

1. French motifs

Thirty years ago, a French consortium of automotive manufacturers developed a graphical method, called R&W motifs aiming to identify structures (or motifs) on profiles that play an active role in the function of surfaces.

Later standardized under the reference ISO 12085, this method defines motifs as the triplet peak-valley-peak. The algorithm described in the standard is based on the identification of local extrema followed by the selection of significant motifs.

When a motif is found to be insignificant, it is merged with one of its neighbors to form a larger one. After selection, only significant motifs remain. Parameters are then calculated to provide the mean height and mean width of these motifs and they can be used in specifications.

This method proved very efficient, especially after a large scale campaign to qualify more than 20,000 mechanical components using these parameters with respect to different functions. This then made it possible to derive guidelines for designers to help them correctly specify the surface texture of components on drawings according to the expected function.

2. Areal features

More recently, a new feature detection method was introduced in the ISO 25178-2 standard. It is based on watershed segmentation of the surface followed by a pruning method aimed at selecting significant features on the surface.

Areal features can be points (peaks, pits or saddle points), lines (ridge or course) or areas (hills or dales) which can then be characterized with numerical values such as heights, areas, volumes, orientation, form factor, etc. They are called feature parameters.

When detecting dales (which are the micro-scale equivalent of catchment basins), the ridge lines around them correspond to contours of the texture cells. Contours around hills are called course lines. This segmentation and the parameters associated with it make it possible to characterize how the surface interacts with its environment through its features. Crucially, they only take into account certain parts of the surface.

Watershed segmentation can also be used to detect shapes. Pre-filtering highlights steep slopes, and the result is a kind of contour detection allowing automatic partition of the surface.

Many applications can benefit from the use of feature parameters. Designers and metrologists must now work together in order to establish functional correlation between these parameters and their process parameters. As was the case for profiles with French motifs, it is anticipated that controlling functions using feature parameters may lead to better correlations compared to the widely used (but somewhat meaningless) Ra!

3. What is functional correlation?

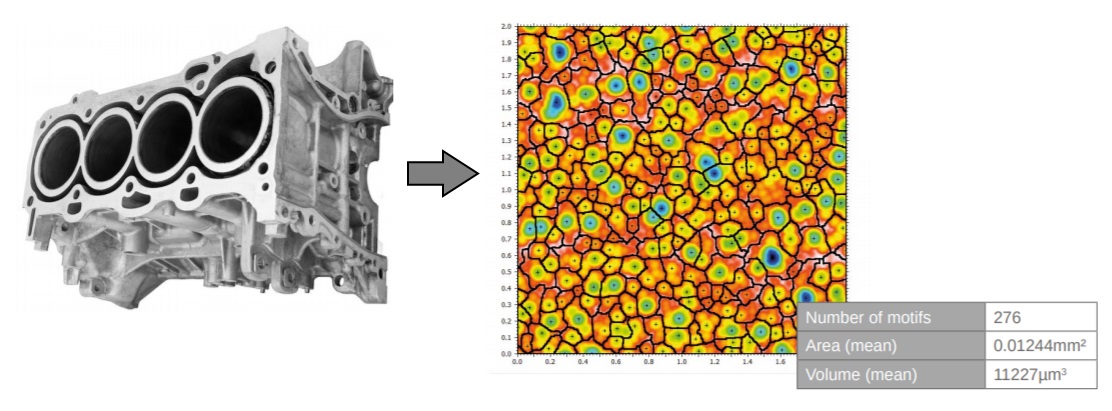

This expression refers to the intended function of a surface on a component as imagined by the designer. For example, the top surface of a cylinder block is supposed to have a sealing function with the opposite surface formed by the cylinder head via a gasket. The sealing efficiency is correlated with the flatness deviation of these surfaces, the height of large hills and the depth of large dales.

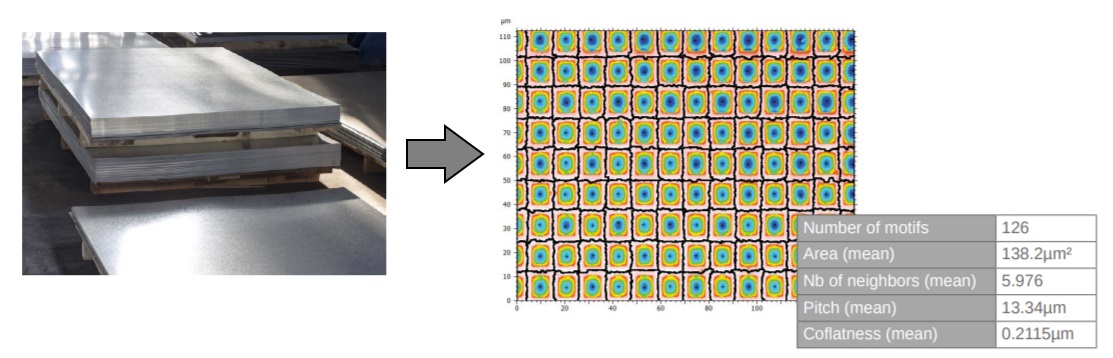

A function on steel sheets is the ability to aid paint adhesion while still being smooth enough to allow press forming tools to slide on the surface without cracks appearing. This function is achieved by texturing small scale patterns onto the surface using rollers (thus creating adequate roughness) but also by leaving enough flat plateaus so that the surface appears smooth at larger scales.

In order to establish which parameter is suitable and connected with the variations of production quality or surface performance, it is necessary to carry out a statistical study on many workpieces, and to search for a correlation between such surface texture parameter and such process parameter or performance indicator. This will later make it possible to use a given parameter in a functional specification on a drawing, because we will know that controlling its value is equivalent to controlling the process or the performance.

Checking the sealing efficiency of a cylinder block. Identification of texture cups and qualification of the mean size, the mean volume and their density.

Steel sheets: obtaining optimal paint adhesion and large-scale surface smoothness. Automatic segmentations of texture cells on the structured surface; detection of missing cells.

Resources

ISO 16610-85: GPS – Filtration – Areal morphological – Segmentation

Feature parameters, chapter 3 in Characterisation of areal surface texture, published by Springer

Areal Feature Parameters, in the Digital Surf Surface Metrology Guide

Segmentation and feature parameters - A corrected definition of watershed segmentation and feature parameters defined in ISO 25178-2, F. Blateyron, Conference proceedings of the International Conference on Surface Metrology, April 2016, on ResearchGate

This text was first published in the Surface Newsletter, Fall 2016.