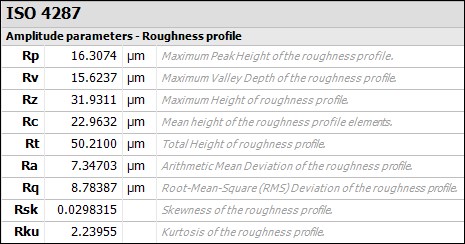

Profile Parameters from ISO 4287

1. Amplitude parameters

Rt, total height of the profile: height between the deepest valley and the highest peak on the evaluation length.

Rp, maximum profile peak height: height of the highest peak from the mean line, defined on the sampling length.

Rv, maximum profile valley depth: depth of the deepest valley from the mean line, defined on the sampling length.

Rz, maximum height of the profile: defined on the sampling length: this parameter is frequently used to check whether the profile has protruding peaks that might affect static or sliding contact function.

Ra, arithmetic mean deviation of the assessed profile: defined on the sampling length. Ra is used as a global evaluation of the roughness amplitude on a profile. It does not say anything on the spatial frequency of the irregularities or the shape of the profile. Ra is meaningful for random surface roughness (stochastic) machined with tools that do not leave marks on the surface, such as sand blasting, milling, polishing

Rq, root mean square deviation of the assessed profile: corresponds to the standard deviation of the height distribution, defined on the sampling length. Rq provides the same information as Ra.

Rsk, skewness of the assessed profile: asymmetry of the height distribution, defined on the sampling length. This parameter is important as it gives information on the morphology of the surface texture. Positive values correspond to high peaks spread on a regular surface (distribution skewed towards bottom) while negative values are found on surfaces with pores and scratches (distribution skewed towards top). It is therefore interesting when contact or lubrication functions are required. However, this parameter does not give any information on the absolute height of the profile, contrary to Ra.

Rku, kurtosis of the assessed profile: sharpness of the height distribution, defined on the sampling length.

Rc, mean height of profile elements: defined on the evaluation length. This parameter can be calculated on surfaces having texture cells or grains. It is similar to the motif parameter R found in ISO 12085 and, in that sense, it should be considered as a feature parameter (see ISO 25178).

2. Spatial parameters

RSm, mean spacing of profile elements, defined on the evaluation length*. This parameter is interesting on surfaces having periodic or pseudo-periodic motifs, such as turned or structured surfaces. In these cases, RSm will approximate their spacing. RSm is meaningless on random surface texture.

* Initially defined on the sampling length, it is now recommended to calculate it on the evaluation length.

3. Hybrid parameters

Rdq, root mean square slope of the assessed profile, defined on the sampling length. Rdq is a first approach to surface complexity. A low value is found on smooth surfaces while higher values can be found on rough surfaces having microroughness.

RPc, peak count number. Was introduced in Amendment 1. Provides the density of peaks per unit of length.

4. Functional parameters

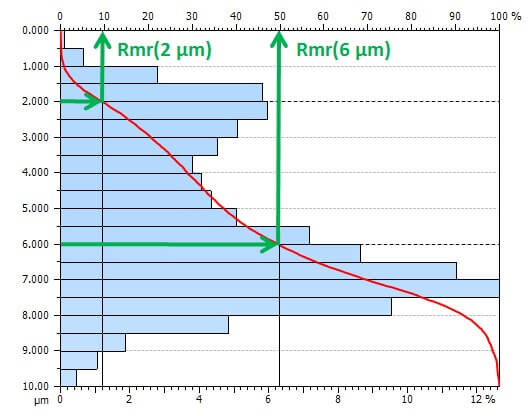

Rmr, material ratio at a given depth. This parameter gives the percentage of material cut at a given depth from the top of the profile. The reference may also be taken from the center line or another reference height (c0).

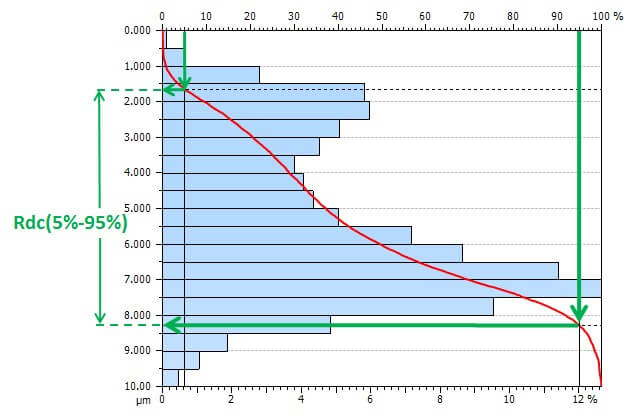

Rdc, profile section height between two material ratios. A stable value of roughness height can be evaluated using Rdc(2%-98%) if outliers are present on the surface. This calculation excludes the highest peaks that will be worn out and the deepest valleys that will be filled in. In the automotive industry, the material height removed during running-in can be assessed with Rdc(1%-33%) and the void volume used for lubricant pockets can be assessed with Rdc(25%-99%).

Material ratio calculated on the Abbott-Firestone curve.

Rmr at 2 µm below the highest peak is 10%.

Section height Rdc between 5% and 95% of material ratio is 6,5 µm.

Amplitude parameters of ISO 4287

This video introduces amplitude parameters calculated on profiles, as defined in ISO 4287 and ASME B46.1 standards. Durée : 8 min 50.

Since the publication of ISO 21920-2, the previous standard ISO 4287 was withdrawn. New drawings and surface texture tolerances are supposed to use the new standard now.